top of page

Taylor McKenzie Parker

Mechanical Design Engineer

PRESS MACHINE TENDING

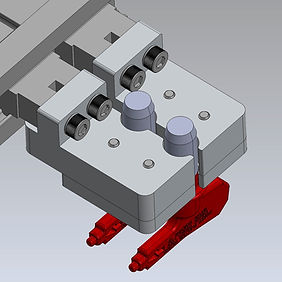

I worked closely with a fellow mechanical engineer at Rapid Robotics to develop an automated assembly and marking system. Our objective was to leverage two UR5e robotic arms in conjunction with the customer's existing stem and stamp press machines. We meticulously designed the work cell layout, electronics cabinets, input trays, sensor brackets, pneumatic end effectors, and a handoff fixture. Furthermore, we specified the guided pneumatic cylinders, magnets, and photoelectric sensors used, all while coordinating essential modifications required for on-site equipment.

bottom of page